Product Parameters

| Feature | Specification |

| Molding Size (Build Volume) | 400 x 400 x 600 mm |

| Extrusion Method | Double screw extrusion with closed-loop servo motor |

| Printing Material | Terracotta, Ceramic, Purple sand clay, Silicone rubber, Cement, etc. |

| Nozzle Diameter | 1~3 mm |

| Printing Layer Thickness | 0.2~3 mm |

| Printing Speed | 30~150 mm/s |

| Extrusion Speed | 10~50 mm/s |

| Positioning Accuracy | ≤0.1mm (≤100mm) |

| Material Bin Volume | 3.9L (approx. 7kg) |

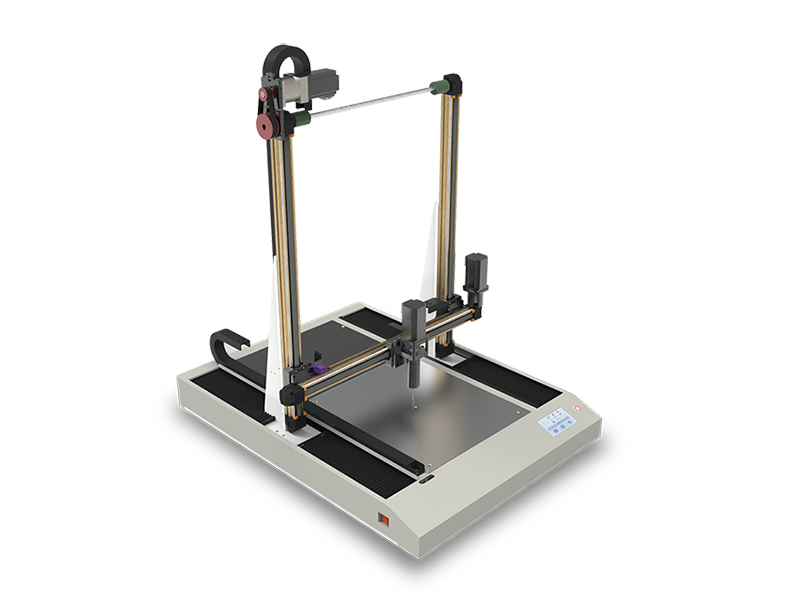

| Frame Style | Open Gantry ("Dragon Gate") |

| Printer Size | 750 x 1050 x 1000 mm |

| Equipment Net Weight | 100 kg |

| Control Panel | 5-inch TFT Touch Screen |

| Printing Mode | SD card offline printing |

| Slice Software | Smart Slicer |

| Compatible Formats | STL, OBJ |

| Operating System | Windows XP / WIN7 / WIN8 / WIN10 |

| Power Voltage | AC 220V / 50Hz |

| Rated Power | 800W |

Expansive Build Volume: A massive 400 x 400 x 600 mm molding size empowers you to create large-scale architectural models, full-size sculptures, custom furniture components, and ambitious pieces without restriction.

Powerful Double Screw Extrusion: Features an advanced double screw extrusion system powered by a servo motor with closed-loop control. This provides exceptionally strong, stable, and precisely controlled power, ensuring consistent flow and superior quality even with thick materials.

Extreme Material Versatility: Go far beyond standard clay. This printer is engineered to handle a wide array of fluidic and viscous materials, including terracotta, ceramic, silicone rubber, and even cement mixtures, opening doors for architectural, industrial, and artistic innovation.

Industrial-Grade Capacity & Stability: Built for serious production, the 3.9L (7kg) material bin minimizes refills for long, uninterrupted prints. The robust 100kg open-gantry (Dragon Gate) frame ensures maximum stability, reducing vibration and enhancing print accuracy.

Professional Control & Precision: Combines high ≤0.1mm positioning accuracy with an upgraded 5-inch TFT touch screen. Paired with "Smart Slicer" software and reliable SD card offline printing, this machine offers an intuitive and precise workflow for complex projects.

Powerful Double Screw Extrusion: Features an advanced double screw extrusion system powered by a servo motor with closed-loop control. This provides exceptionally strong, stable, and precisely controlled power, ensuring consistent flow and superior quality even with thick materials.

Extreme Material Versatility: Go far beyond standard clay. This printer is engineered to handle a wide array of fluidic and viscous materials, including terracotta, ceramic, silicone rubber, and even cement mixtures, opening doors for architectural, industrial, and artistic innovation.

Industrial-Grade Capacity & Stability: Built for serious production, the 3.9L (7kg) material bin minimizes refills for long, uninterrupted prints. The robust 100kg open-gantry (Dragon Gate) frame ensures maximum stability, reducing vibration and enhancing print accuracy.

Professional Control & Precision: Combines high ≤0.1mm positioning accuracy with an upgraded 5-inch TFT touch screen. Paired with "Smart Slicer" software and reliable SD card offline printing, this machine offers an intuitive and precise workflow for complex projects.